Float Carburetors are cheaper than alternatives but not very reliable. Then Ethanol arrived and the poor reliability was mad far worse because Ethanol is a solvent.

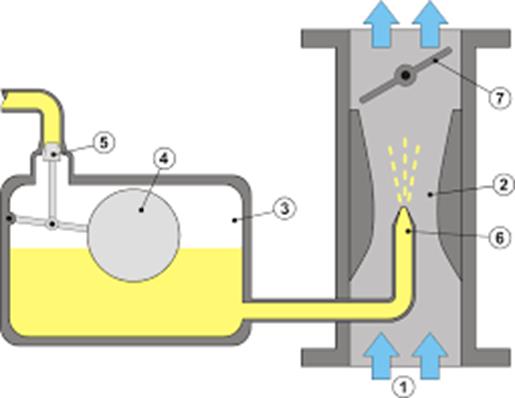

This image I borrowed does not show an important passage called the atmospheric vent. Number 5 is the needle which controls the incoming fuel rate based on the level of the fuel that number 4, the float, controls. The venture number 2 creates a low pressure due to the air flow shown as blue/1 and is lower than the pressure in the cavity where 3 is because number 3 has the not shown atmospheric vent keeping pressure down on the surface of the fuel at atmospheric pressure which is higher than at the venture at 2. This creates fuel to flow out nozzle 6 at a rate relative to air flow controlled by 7. The level of the fuel in the bowl also impacts the fuel rate. So, level in the bowl, air flow through venture 2, atmospheric pressure in the bowl, and as a result, float and needle function effect operation. The float and needle failures are many types. A stuck needle prevents fuel from allowing flow or limits fuel flow or may be stuck from stopping flow and too much fuel flows. Float may stick on the bottom or not have proper movement or not float because of leakage into the float making it heavy. This causes excessive flow into the bowl. There are other failure types, but I think you get the idea, with the end result of engine function not explained. When too much fuel flows in, first the engine runs rich and the exhaust may become black, the plug may become fouled, and it eventually fuel flows out the atmospheric vent and dribbles down along side the carburetor and drips down. If flue flow is not sufficient for required running load, then the bowl will get low, the engine will run lean and eventually quit from lack of fuel. One last more commonly found and dangerous condition exists when equipment is stored and where stored: Temperature changes and factors of time and ethanol make the needle stick and fuel flows by gravity out the vent and on the floor waiting to catch fire or at least preventing a once well running machine no longer start.

FLOAT FAILURE WE CANNOT PROTECT YOU AGAINST! If the equipment has a fuel shut off valve, we suggest it be used.